Email :

Address :

- W305 Al Saaha Offices The Palace Downtown Burj Khalifa, Dubai, UAE P.O. Box 418288

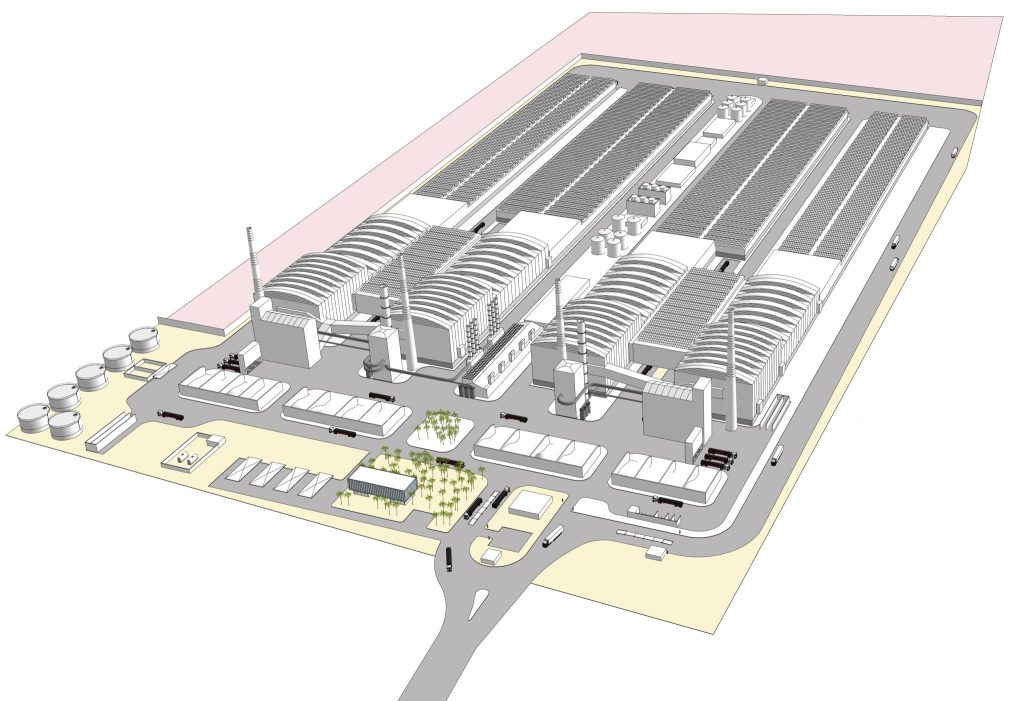

An advanced glass bottle manufacturing plant with an annual production capacity of 480,000 tons is being developed in Baghdad. The facility will produce a wide range of bottles and jars in sizes from 80 mm to 500 mm and weights from 40 grams to 500 grams, across multiple designs, molds, and colors. Production will utilize Soda–Lime–Silica glass, with outputs including honey-brown (amber) and various colored glass products.

Phase I – Installation of a 400 TPD furnace supporting four high-speed production lines in a triple-gob configuration, using the NNPB process, optimized for CSD (carbonated soft drink) bottles.

Phase II – Addition of a 400 TPD furnace with two flexible lines in a double-gob configuration, utilizing the WMPB process for food jar production.

Phase III – Installation of a further 400 TPD furnace with two flexible lines in a double-gob configuration, applying the B&B process for large-format bottles used for juices, water, and syrups.

Phase IV – Expansion with an additional 400 TPD furnace and two flexible lines in a double-gob configuration, designed to alternate between large bottles and jar containers, enhancing production versatility.

The plant is strategically located in South Baghdad on a total land area of 367,000 square meters, providing sufficient space for future expansion and efficient operations.